Biebl® 1,3-PDO: The Bio-based PDO Revolution – Ending the Food vs. Fuel Dilemma

Biebl®: Rewriting the PDO Story – From Petrochemical Dependence to Bio-Based Innovation

The Petrochemical Era

For decades, crude oil reigned as the "gold standard" of chemical production. Conventional 1,3-propanediol (PDO) manufacturing relied entirely on two petroleum-based routes:

1、 Ethylene oxide hydroformylation

2、 Acrolein hydration

These processes came with hidden costs – volatile oil prices, supply chain vulnerabilities, and unsustainable environmental footprints.

The Bio-Based Revolution

Biebl® disrupts this paradigm through:

✔ Non-petroleum feedstocks (agricultural residues/non-food biomass)

✔ Carbon-negative fermentation (vs. oil refining's high emissions)

✔ Supply chain resilience (decentralized production possible)

Extreme conditions: need to react in high temperature and high pressure environment, huge energy consumption.

Toxic threat: Produces highly carcinogenic intermediates that pose risks to people and the environment.

Trapped in the Fossil Fuel Trap: Reliance on finite petroleum reserves worsens carbon emissions and global energy instability.

As the world races toward carbon neutrality & carbon peak, the high-pollution, high-risk petrochemical PDO era is ending—ushering in the age of bio-based PDO.

This shift isn’t just policy-driven—it’s fueled by bio-based PDO’s unmatched performance in cutting-edge applications like cosmetic moisturizers and biodegradable fibers.

Bio-Based Technology: When Ideals Meet Practical Challenges

The Three Bottlenecks of Current Bio-Based PDO Production

1. The Food Security Paradox

Most conventional bio-based PDO relies on corn starch fermentation, consuming significant grain supplies per ton of PDO—directly conflicting with global food crisis concerns. Since 2022, soaring food prices have further inflated production costs, making this model unsustainable.

2.Biosafety Risks: The Hidden Cost of Pathogenic Strains

Traditional strains (such as E. coli, Klebsiella pneumoniae, etc.) are pathogenic and need to be sterilized, resulting in increased investment in fermentation equipment and rising energy consumption costs.

3.Carbon Reduction Limits: The Aeration Dilemma

The traditional fermentation technology uses aerobic fermentation, which requires a lot of ventilation. The production process generates 2.78kg CO2/kg PDO in across its entire lifecycle.

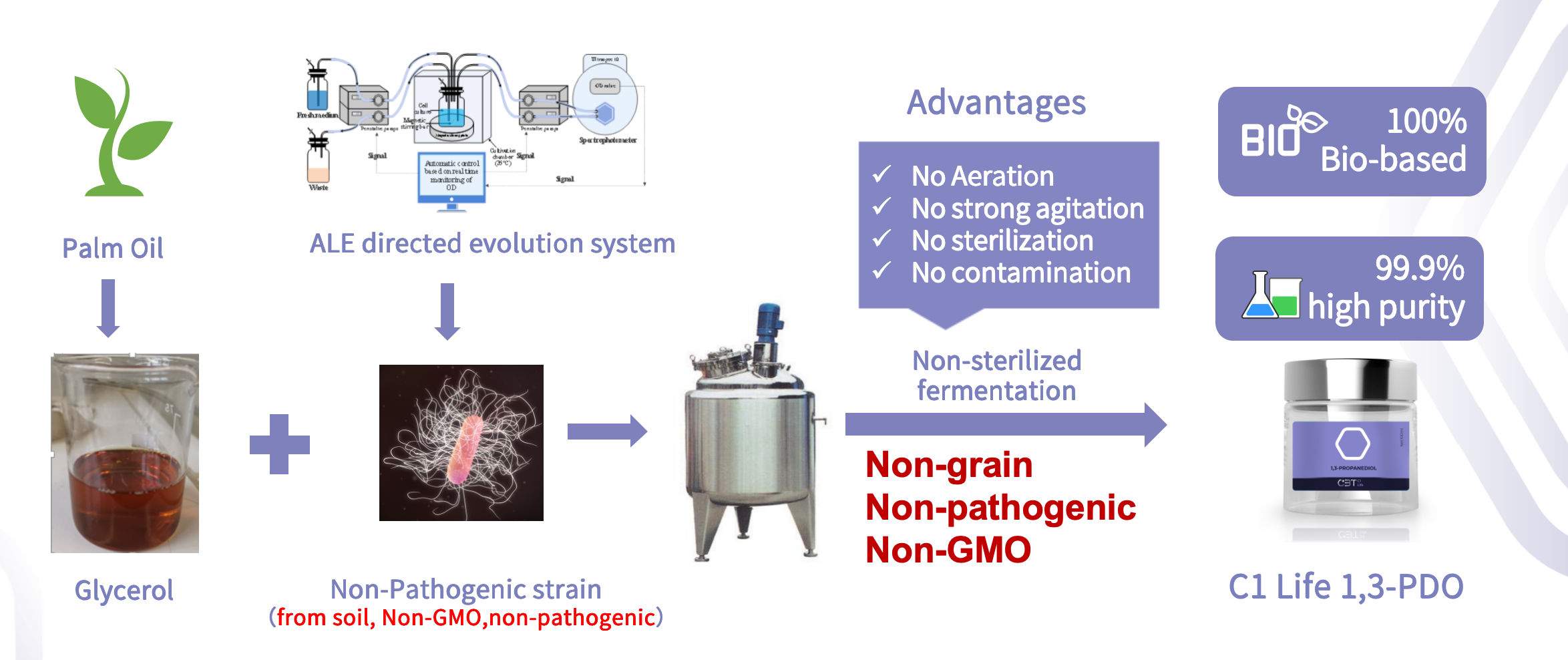

C1 life: Pioneering the Green Revolution from Soil to Factory

After years of dedicated R&D, Guangdong C1 LIFE BIOTECH has successfully developed the world's first 1,3-propanediol (PDO) derived from non-GMO, non-grain sources, and non-pathogenic bacteria. This breakthrough not only overcomes the three major industry bottlenecks but also redefines the very logic of PDO production.

@Microbial Breakthrough: Redefining PDO Production

Through proprietary R&D, C1 Life has pioneered a game-changing strain—developed by screening natural soil microbes and optimizing. This technology delivers:

✔ Non-GMO & non-pathogenic by design – No genetic modification, no safety risks

✔ Unmatched efficiency – 0.5g PDO/g glycerol conversion even at ton-scale

✔ Industry-leading yield – >110g/L PDO concentration in fermentation broth

✔ Pharma-grade purity – 99.9% pure PDO after purification

@Process Optimization: C1 LIFE groundbreaking fermentation technology with No ventilation, no strong stirring, no high temperature sterilization, no expensive nutrients- dramatically to reducing production costs . The by-products such as acetic acid and butyric acid produced in the fermentation process can be further purified and processed into high value-added products such as organic acid esters.

@Low carbon and grain safty: Biebl® Bio-base 1,3-PDO derived from natural and renewable resources—specifically glycerin, a byproduct of vegetable oil hydrolysis—this non-food feedstock completely replaces traditional petroleum-based raw materials while eliminating any competition with global food supplies.

This bio-based sourcing significantly reduces reliance on synthetic chemicals, minimizing potential chemical risks while meeting stringent global standards for green, natural, and sustainable ingredients.

Biebl® Bio-Based 1,3-Propanediol dramatically lowers carbon footprint and energy consumption during use—perfectly aligning with low-carbon, eco-conscious production principles. This makes it a crucial solution for both brands advancing sustainability strategies and consumers demanding greener choices.

C1 LIFE Biebl® 1,3-Propanediol represents more than just a technological breakthrough—it sets a new standard for green manufacturing. This innovation proves that industrial progress and ecological harmony can coexist without compromising performance or profitability.

- C1 Life Concludes Successful Showcase at In-Cosmetics Asia 2025: Bio-Based Solutions Advance Sustainable Beauty In Asia-Pacific

- C1 Life to Showcase at In-Cosmetics Asia 2025 with Innovative Bio-Based Solutions

- Biebl® Bio-Based PDO Makes Its Debut in South America: C1 Life Technologies and DPV Showcase at In-Cosmetics Latin America 2025

- Two Events in July: PCT2025 Shanghai & In-Cosmetics Korea

- Biebl® Bio-based 1,3-Propanediol: A Naturally Derived Ingredient Excelling in Safety and Skin Feel

- Biebl® 1.3-PDO: Bio-based Moisturizing & Preserving: A New Standard

Newscenter

Newscenter